Riding high

Research news

In the world of cycling, it seems that choice of high-tech frame material does, in part, come down to fashion.

“Titanium is currently a valuable commodity in cycling,” said Deakin engineer Dr Paul Collins. “It is very expensive, but it is corrosion resistant and very strong for its weight.”

“While titanium is roughly equivalent to carbon fibre by certain measures, it has an interesting, more lively feel and it is the material of choice for connoisseurs of cycling.”

Dr Collins, who lectures in design and product development at Deakin’s School of Engineering, has established an ongoing relationship with Geelong’s elite bicycle manufacturer Baum Cycles, with the two working on projects together to create ever more sophisticated, customised bikes for racing, touring and mountain bike riders.

Baum Cycles is one of Geelong’s quiet achievers, with an international reputation as a world leading high-end bespoke bike manufacturer. The company employs seven people and exports a third of its products to six countries. The majority of its bikes are custom made, with a starting price of around $7000.

The collaboration is proving mutually beneficial for Deakin and Baum, with Deakin students getting experience in solving “real world” design problems, and Baum having access to Deakin’s brain power and state-of-the-art technology.

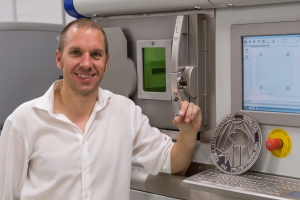

In the latest project, Dr Collins has helped develop a titanium drink bottle holder for a Baum bike.

The resulting holder might look simple, but it took significant technology to provide the final solution, which is a very small, highly sophisticated titanium bracket that “morphs” into the frame and uses a rare earth magnet - the strongest type of magnet available - to hold the bottle in place.

Luckily, Deakin’s engineering school owns a brand new $700,000 3D printer that prints titanium and stainless steel. One of only a handful of titanium 3D printers in Australia, the printer was one of the first pieces of equipment purchased in readiness for Deakin’s new $55 million Centre for Advanced Design in Engineering Training (CADET), which is expected to be completed at Waurn Ponds by next year.

The facility will provide the most advanced engineering and design training capabilities in regional Australia. It will feature more than $6 million worth of cutting edge technologies and offer programs from Year 8 through to PhD level, linking secondary, VET and tertiary education.

Dr Collins said that a key feature of CADET will be its focus on “producing engineering graduates who have the creative, design-focussed skills that will help them to thrive in a new era of manufacturing in the Australian and global landscape.”

The relationship between Deakin and Baum Cycles began around four years ago when the two worked together on a “future concept smart bike” that featured sensors embedded in the carbon frame. These allowed the rider to make smart decisions about their performance by measuring strain in various parts of the bike. Technology and design features from the “smart bike” have been a starting point for conversations about aspects of Baum’s bikes.

Owner of Baum Cycles, Darren Baum, said that the collaboration with Deakin has been “all about solving engineering problems.”

“Smaller businesses and universities are so different,” he said. “We are about having a product to sell. We have a commercial agenda - to solve a specific problem and create a product that makes money. However, despite our differences, we have developed a really strong foundation of language that allows us to work together very effectively.”

Share this story

Dr Paul Collins with the drink bottle holder and the 3D titanium printer that created it.

Dr Paul Collins with the drink bottle holder and the 3D titanium printer that created it.