About the lab

The state-of-the-art facilities and equipment at the Structural Engineering Lab support applied and discovery research in the area of structural and mechanical engineering. The lab allows us to manufacture and test innovative and hybrid structural elements using emerging construction material, including:

- hardwood cross-laminated timber (CLT), hardwood-softwood hybrid CLT

- BFRP (basalt fibre reinforced polymer) – geopolymer composite rebar

- BFRP-LVL (laminated veneer lumber) composite beam

- sustainable, durable and high-strength concrete element

- steel-timber and/or steel-concrete composite elements

- innovative connection system.

Equipment and technology

The lab's equipment and technology capabilities include:

Material and large-scale structural testing

- NATA (National Association of Testing Authorities, Australia) certified load frames of 300 and 500 kN capacity – used for bending and compression member

- A 1000 kN NATA certified load frame – used for compression member

- University testing machine for tension and compression member with a capacity of 300 kN

- Standard compression testing of cylinders with a capacity of 3000 kN

- Material testing including porosity characterisation of porous material, resistivity meter for determining corrosion rate, x-ray diffraction, Vicat apparatus for penetration resistance, Scanning electron microscope (SEM) machine, moisture meter and apparatus to determine drying and autogenous shrinkage, internal pH, carbonation, sulphate resistance, petrographic analysis, alkali aggregate reactivity and sorptivity

- Response measurements including strain gauges, linear variable differential transformer (LVDT), laser transducers, crack mouth opening and 3-D video extensometer for digital image correlation

- Compact action (GoPro), DSLR and pro-sensors cameras

- LabView based embedded controller system with real-time data acquisition

Non-destructive evaluation of structure and structural dynamics

Guided wave-based equipment

- NI PXIe-8135 guided wave embedded controller

- NI PXIe-5105 Oscilloscope for guided wave

- NI PXI-5412 Arbitrary waveform generator

- Ultrasonic pre-amplifier

- Contact transducer (1 KHz)

Vibration-based equipment

- NI cDAQ-9133 Compact Data Acquisition System

- Vibration input modulus NI-9232

- Uni-, bi- and tri-axial accelerometers

- Modal hammer for inducing

- Piezocomposite actuator to induce shock wave (voltage range -200 to 1000 V)

- Amplifier for piezocomposite actuator (Voltage 0V to +1000V, peak current 350mA)

- Wind tunnel testing facilities

Durability and simulated environment

- Environmental chamber to control moisture and simulated environment including UV light, with a capacity of 850 litres, temperature range of 10–80 °C and a humidity range of 10–95%

- Weathering tank with temperature control for accelerated ageing (up to 60°C) and controlled for simulating a wet-dry cycle

Mechanical workshop

- General purpose workstations, hand tools and cordless power drills

- Docking facilities and panel, drop, band (vertical and horizontal) and circular saw

- Laser cutting (Tropec Speedy 500)

- 5-axis water jet cutting (OMAX)

- Lathe machine

- 3D printing

- 500kN and 3000kN load frames – used for bending and compression with load and displacement control along with cyclic load frequency. LVDT and laser displacement, strain and crack opening responses available

- 1000kN horizontal load frame, with compression, load and displacement control, along with cyclic load frequency. LVDT and laser displacement and strain responses available

- 300kN load frame – used for tension and compression tests, load and displacement control

Teaching applications

Engineering students use the lab for practical learning and when undertaking their final-year projects. Projects can use various construction materials such as timber, fibre-reinforced polymer, concrete, geopolymer, steel and aluminium. Students are able to observe and analyse the material and structural behaviour of these emerging construction materials and innovative structural system.

Some projects include:

- using recycled plastic and glass in concrete

- fly ash and slag based geopolymer suitable for heat and ambient curing

- development of basalt fibre rebar with improved compressive strength

- material characterisation of Australian hardwood and softwood

- development of hybrid timber system using various wood species

- fibre-reinforced concrete beams and composite and hybrid structural element using two or more construction materials (e.g. concrete, fibre-reinforced polymer, geopolymer and steel).

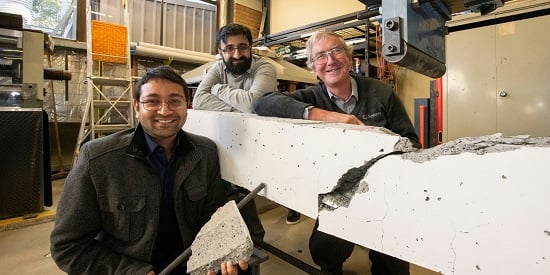

Research applications

Our facilities allow for applied and discovery research that has attracted numerous industry-based research projects. These projects have been in areas related to timber engineering, concrete structure, geopolymer concrete, development of innovate structural systems for structural application, and novel hybrid structural systems using multiple construction materials.

Some highlighted projects include:

Maintenance-free bridge

Deakin researchers designed a pedestrian bridge using a new type of reinforced concrete to help avoid the corrosion problem that occurs in conventional steel reinforced concrete construction.

Industry collaboration fosters new ideas and concrete results

A Deakin research group tested and analysed the behaviour of newly developed composites and structures to improve their mechanical performance and durability.

Industry partners

Our partners become valued members of the wider Deakin engineering family, not just our school. Opportunities to partner with us include work-integrated learning and industry-based learning and placements, student projects, and commercial research projects and services.

Study with us

Deakin offers the following study and research options:

- Undergraduate students can study through our Bachelor of Engineering (Honours).

- Postgraduate students can study throughout Master of Engineering (Professional).

- Research studies can be undertaken through our Doctor of Philosophy (PhD) higher degree by research degrees.