Deakin showcases global breakthrough in nanotube technology at Airshow

Media releaseDeakin researchers will unveil the world's first 3D-printed Boron Nitride Nanotube-Titanium composite at the Australian International Airshow on Friday, with the milestone technology set to garner widespread interest across aerospace and defence industries.

The breakthrough from Deakin's Institute for Frontier Materials (IFM) affirms Deakin's place as a global leader in nanotechnology and will help drive demand for Boron Nitride nanotubes (BNNT) in a number of areas by unlocking its end-application potential.

IFM researcher Professor Ian Chen said the work was a huge advancement in both nanotube application and 3D printing, also known as additive manufacturing.

Professor Chen said he was excited about the possibilities it could usher in for industries across the globe in the production of components that utilise the unique properties of BNNT and titanium.

"While titanium composites have been widely used in aeroplanes, in defence and high-end equipment, a composite with nanotubes will make the material stronger, lighter, give it a longer life and high-temperature tolerance," he said.

"These nanotubes have many unique properties and the new composite will bring in new possibilities and applications."

Deakin Deputy Vice-Chancellor Research Professor Peter Hodgson said the world-first result of 3D printing a BNNT-Titanium composite showcased the innovation of researchers at the university and placed them at the cutting-edge in their fields.

"Deakin's nanotechnology research and achievements will make a positive difference across the globe, bringing disruptive changes to a wide range of industries in the years to come," Professor Hodgson said.

"Nanomaterials are a bright new frontier and Deakin's researchers are excellent pioneers when it comes to scientific exploration."

BNNT, with its tubular structure, incredible strength, light weight and ability to withstand intense heat, has sparked strong competition among researchers in countries including Australia, Canada and the USA over the past two decades as they race to find effective pathways to commercial production.

So far these advanced nanomaterials, which are difficult to make, can only be created in small amounts, limiting their product development opportunities.

But Deakin's nanotechnology group, led by Professor Chen, has developed a unique and scalable manufacturing process that has the capacity to turn BNNT into a major player in the marketplace.

The patented production technology, which uses ball milling and annealing processes, is already a proven performer in the laboratory and when scaled up will have a major impact on industries including automotive, defence and aviation when commercialised. Deakin plans to set up a commercial BNNT pilot plant in Geelong to produce the nanomaterial in kilogram quantities as soon as possible.

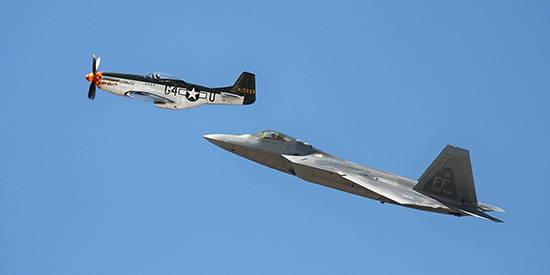

IFM's nanotechnology research is a key part of the Deakin's display at the Avalon-based Australian International Airshow and Aerospace and Defence Exposition this week.

The trade-show, which began on Tuesday, will attract representatives from government organisations and industries across the world before the airshow gates open to the general public on Friday afternoon.

About 30 Deakin researchers and staff will display innovative research, technology and projects across a wide range of fields, providing an interactive experience for people at the Avalon events.