Working with Carbon Nexus

Carbon Nexus is one of the world’s leading carbon fibre and composite research facilities, where IFM researchers deliver globally significant, university based, industrial scale research.

The Institute for Frontier Materials (IFM) creates and translates knowledge to globally raise standards of living by redesigning materials for a circular economy and imparting materials that provide us with extraordinary functionality.

No longer can we keep adding functionality via tailored complexity for a single life. Much effort has been expended on how to best recycle, reuse and repurpose our existing materials. The next frontier is to build multiple life functionality into new materials.

IFM explores how to best tailor materials for repurposing, disassembly, reassembly, longevity and finally for recycling, all the while maintaining the highest possible performance and value.

We want materials that adopt new shapes, last almost forever, transform devices, interact with us and please us like natural materials do. We want materials to clean water, safely power electric vehicles, save energy, and in short, transform society.

These challenges are substantial and the breakthroughs in extraordinary functions frequently come at the atomic level, or with a new scientific discovery. The journey to functionality is an exciting one that opens up whole new technological advances.

IFM’s research spans the spectrum of materials research from fibres and textiles, to carbon fibre and composites, advanced alloys and infrastructure materials, and electro and energy materials.

Our team works on problems across fundamental and industrial scales. Specialisms include steel, aluminium, magnesium, coatings, high entropy alloys, characterization and forming.

Our research is designed to increase profitability and competitiveness, extend product life and reduce energy consumption.

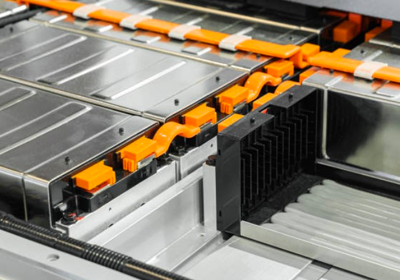

The key focus for the electro and energy materials theme is battery materials and technologies.

Its team have pioneered research into novel electrolytes and alternative battery technologies such as lithium and sodium batteries and metal-air batteries.

IFM develops material solutions in fibres and textiles, investigating ways to repurpose and recycle textile waste as well as designing new materials and processes with added functionality.

In the area of Carbon Fibres and Composites, our researchers are addressing challenges to reduce the cost, increase performance and reduce manufacturing time of carbon fibre and composite materials.

Work on immersive, innovative projects to address material challenges in the energy, mining, environment, health, transport, textiles and manufacturing sectors.

IFM has always been an exemplar for how research organisations can build and lead a culture of impact and industry collaboration within a university and a region

Professor Sally McArthur

Director, Institute for Frontier Materials

Our partnerships with industry allow us to translate our research into real-world impact. We lead bold initiatives that seek solutions beyond traditional research and organisational boundaries.

Carbon Nexus is one of the world’s leading carbon fibre and composite research facilities, where IFM researchers deliver globally significant, university based, industrial scale research.

IFM researchers are on track to create the first commercially viable next generation lithium sulphur battery, a battery that is cheaper, lighter and more efficient than anything else on the market.

IFM brings together the expertise of researchers from all over the world, and from many different research areas including engineering, chemistry, textile science and molecular modelling.

Professor Sally McArthur is the Director of IFM. She is a biomanufacturing expert whose research uses engineering principles to improve human wellbeing. She has extensive experience in developing industry-academic research collaborations, which was recognised with a Fellow of the Australian Academy of Technology and Engineering in 2021.

Alfred Deakin Professor Maria Forsyth is the Associate Director of IFM. She is a world expert in 'one of the most important issues in the world today', advancing energy storage and novel corrosion mitigation technologies.

Professor Matthew Barnett has made significant technical contributions to alloy development in sheet steel research, light metals development, alloy characterisation and alloy functionality. His area of research involves designing the microstructure of new metal alloys to give enhanced properties.

Through active engagement with our partners, industry and communities, our research endeavours to create real world solutions of transformational benefit to society.

Stay in touch to hear about the latest alumni opportunities, research news, partnership and industry opportunities, and much more. Have a question? Get in touch with the team.

03 5227 2013

Email the IFM team

LinkedIn: IFM’s LinkedIn

Visit the IFM website