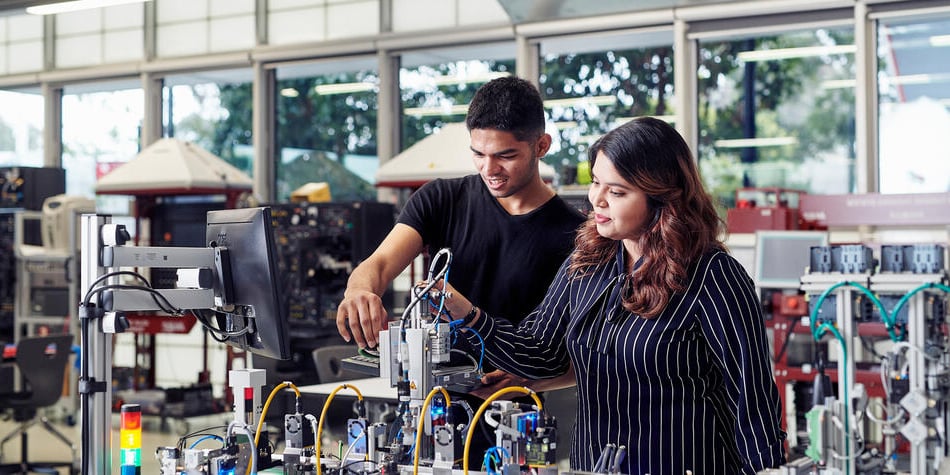

Work-integrated learning

We offer industry-based learning placement programs, industry-driven capstone projects, combined student placement and project programs, and industry-based PhD or masters research programs. As a Bachelor of Engineering (Industry) (Honours) student, you’ll also spend a year in industry as part of your course.