Printed circuit boards

T-Tech Quick Circuit QCJ5

The T-Tech Quick Circuit QCJ5 is a 3-axis CNC milling machine. It has a 60,000rpm spindle specifically designed for producing printed circuit boards and has the capability to produce single and double sided PCBs with a maximum size of 300mm x 220mm.

Visit the manufacturer’s website

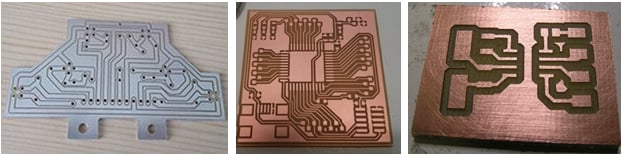

Typical work pieces

Available tools

The following table details tool sizes available in the Mechatronics PCB mill. Your PCB Design minimum clearances and hole sizes should be matched to suit this tooling.

| Type | mm | thou/mil | Notes |

|---|---|---|---|

| Drill | 0.60 | 23.62 | Transistors –TO-92 / small diodes – 1n4148 etc… |

| Drill | 0.70 | 27.56 | |

| Drill | 0.80 | 31.5 | 1/4 Watt resistors etc. |

| Drill | 1.00 | 39.37 | Pins and diodes – 1N4004 etc. |

| Drill | 3.175 | 125 | Holes for screws / standoffs etc… |

| End mill | 1.59 | 62.5 | |

| 2.03 | 80 | ||

| 3.175 | 125 | ||

| Pointed mill | 0.20 | 8 | Minimum clearance between tracks and pads |

| 0.25 | 10 | Preferred minimum clearance | |

| 0.30 | 12 | ||

| Contour router | 2.03 | 80 | Board outline / cut-out. Can also be used for holes |

Producing a board

To get a PCB produced, email the gerber and drill files to sebe-eng-pcb@deakin.edu.au. You will be informed by email when your board is complete.

File preparation

Instructions are based on DipTrace. Please take note of design restraints.

View information on how to prepare a file (PDF, 123.5KB)

Exporting Gerber and drill files

Once the board design is complete, Gerber and drill files will need to be created and sent to sebe-eng-pcb@deakin.edu.au.

Single sided boards will require 3 files:

- Tracks (Gerber).

- Board Outline (Gerber).

- Holes (Drill).

2 sided boards will also require a second tracks Gerber file.

Download eagle to Gerber instructions (PDF, 453.1KB) (PDF, 742.2KB)